“

We like challenges because we grow through them.

Our mission is to deliver the right solution for the most difficult

and challenging requests from our customers

”

-

Who we are

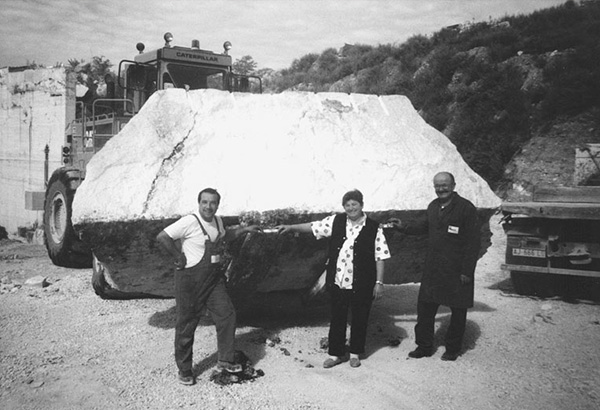

CORAZZA was founded in 1968 by Luigi Corazza with a deep sense of innovation,

which is daily inspiring us since more than 50 years

First in Italy to use Swedish special wear-resistant steelx, today known as HARDOX®,

and to be awarded as HARDOX IN MY BODY company. Range of special attachments expanded into marble/granite quarryin in 1990 by introducing a very innovative design in forks for block handling

As a successfull family business, CORAZZA is now managed by Claudia Corazza, daughter of the founder Luigi, and her husband Fabio Romanut.

Continuous improvemt and search for the best solutions to support customers make CORAZZA a market leader in attachments for mining and construction

-

HOW WE WORK

CORAZZA attachments are designed around customers' needs, not from a generic offer.

Utmost care is used throughout the production process: steel selection, welding, grinding and cleaning

We only use genuine SSAB HARDOX® 450 and 500, HARDOX® HiTuf and new HARDOX® 500TUF and HARDOX® HiAce,

in very high percentage. Different grades are accurately selected according to materials to each specific applicaiton, materials to handle or dig, working temperature and time of use

The exclusive process of preheating in large furnaces

delivers the strongest buckets and the highest durability even in the harshest working conditions. Before delivery, all products go through severe quality controls of the weldings: both magnetoscopic and ultrasounde checks are performed by third-parties independent specialist

Full in-house production process through high precision CNC machines

total control on each step of the process to grant highest quality and matching expected timing

-

OUR WAY

-

CERTIFICATIONS and AWARDS

- Quality management system certification ISO 9001

- Environmental management system certification ISO 14001

- Health and safety management system certification ISO 45001

- 2003: first Italian company to be awarded as 'Hardox® in My Body' company

- Hardox® WearParts certified company from Swedish steel manufacturer SSAB: designing and manufacturing components made out from HARDOX®, STRENX®, TOOLOX® special steels.

- Samoter 2006 Award for innovation, for the Speed Pipe product, at the Samoter fair in Verona